MagnaFlow Minute: Catalytic Converter Collectors

Welcome to this episode of the “MagnaFlow Minute,” where we give you some quick facts about the construction or design of our product and why the MagnaFlow Difference matters. Today we are talking all about merge collectors!

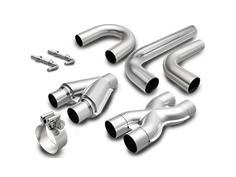

MagnaFlow uses a stamped merge collector which is commonly used in exhaust systems with “V” or opposed cylinder configurations. A stamped merge collector takes multiple exhaust flows, such as those from different banks of an engine, and merges them into one. Most other manufacturers will often bypass the use of stamped merge collectors and instead will splice or crush pipes together to create a union, avoiding an investment in tooling. At MagnaFlow, all our merge collectors are manufactured utilizing a stamped design.

This process is precise, resulting in high quality parts and more efficient exhaust flow throughout the catalytic converter. Alternatives using the spliced or crushed process are prone to manufacturing variations. These variations may result in altered air flow leading to improper engine operation and/or converter failure. You may also find multiple exhaust leaks at the joint due to the inconsistent manufacturing process.

When engineering a catalytic converter, it is important to consider what impact the design will have on the vehicle’s back pressure. If back pressure is increased, the result is a decrease in fuel economy and engine performance. A poorly executed union is a common culprit for an increase in back pressure. At MagnaFlow, we will use merge collectors closely resembling the design of the original part on your vehicle.

Utilizing our flow bench as part of the engineering process, we confirm our newly designed converters work with the vehicle’s original design. By ensuring the back pressure characteristics of the original converter are closely mimicked, we preserve fuel economy and engine performance. The stamped merge collectors used by MagnaFlow result in a consistent exhaust flow.

This consistency means that the amount of heat concentration is optimized, avoiding the creation of any failure points within the converter. You will find that the alternative converters on the market using spliced or crushed unions may experience premature failure due to changes in the heat profile in a given area of the tubing. Here at MagnaFlow we consider OEM design parameters when manufacturing our catalytic converters. This design standard means that when a merge collector is required, we consider the OEM requirements and maintain the structural integrity.

Counterparts using spliced or crushed unions are not following the OEM parameters, leading to reduced and inconsistent exhaust flows as well as a weaker structural integrity. When replacing your converter, MagnaFlow maintains OEM strength, fuel economy, and engine performance with optimal exhaust flows. The stamped merge collector is a crucial part of our catalytic converter offerings.

Tune in to the next MagnaFlow Minute for another easy reason why we should be your number one choice for catalytic converters. Check out our other MagnaFlow Minute videos below or read about why the MagnaFlow difference matters, here.

WATCH THE FULL PLAYLIST

Comments