Building the Perfect Trophy Truck with Jerry Zaiden

To learn more about the rugged high-speed off-roaders made for this specific type of driving, we asked Jerry to walk us through building the perfect trophy truck.

After graduating high school in 1991, the pair decided that they would go into business to produce the parts they needed for truck racing. Jerry said, “our goal was always to be racing,” and in 1997, Camburg Engineering was born. With Jerry’s experience in sales and marketing and Jason’s engineering background, they began designing and manufacturing high-end suspension components for racing.

The business partners’ first purchase was buggy powered by a Volkswagen 1600CC engine. Its humble 85 horsepower wasn’t great for a drag start, but “desert racing is all about average speed,” Jerry explained. They soon added a supercharged Toyota V6 powered buggy to the garage with about 250 horsepower. At only 1,800 pounds, it was significantly faster than the VW mill.

Today, Camburg Engineering is the leader in off-road suspension systems and an engineering trendsetter in the field. The same over-the-counter parts offered to customers are race-tested on its highly competitive trucks – that’s some serious R&D!

What is a Trophy Truck?

Jerry told us that a trophy truck is essentially an “unlimited four-wheel vehicle that runs a truck body, but there’s nothing really ‘truck’ about a trophy truck.” Trophy trucks generally feature a full tube chassis, a front-engine layout, independent front suspension, a solid rear axle, and two-wheel-drive propulsion. In the front, there are 24–26 inches of suspension travel, and at the rear, there are 28–34 inches of suspension travel. When it comes to power, levels generally exceed 800 horsepower, but the engines also have a lot of weight to carry. Unlike traditional racing where lightness is valued, a softly-sprung trophy truck needs weight to keep it planted during fast off-road sections and whoops. Jerry’s race trucks ring in at about 6,000 pounds — for reference, a Hummer H3 is just shy of 5,000 pounds.

The Turbo 400

The Turbo 400 is the transmission of choice for most of these trucks, but it can be modified with different torque converters, gearing, underdrive kits and manual valve bodies. The automatic Turbo 400 was first introduced in 1964, and with only three speeds, it's relatively primitive by today’s standards. With that said, it's the perfect transmission for trophy truck racing because of its supreme durability; in this truck’s current configuration, the Turbo 400 can easily handle up to 1,000 lb-ft of torque.

The underdrive kit has more to do with durability than performance. It decreases the speed of the driveshaft, which permits him to use a lower ring-and-pinion ratio, which increases strength. Lastly, a manual valve body allows the driver to shift the transmission instead of a transmission control unit (TCU) that provides automatic shifts.

Suspension

Improving the suspension is an essential modification made to a trophy truck, and it just happens to be Camburg’s specialty. Camburg offers several upgraded suspension parts for trophy trucks, and through their premium brand Kinetic, they provide some of the most advanced components in the industry.

Camburg suspension parts are back-beveled before welding, which increases the mating surface area of different metal components. Back-beveling is a time-consuming process, but it ensures better weld penetration and durability. Kinetic suspension parts are differentiated by their billet construction and the use of TIG welding. The billet construction helps to keep weight down while providing impressive strength. Although we could go into the nitty-gritty details of the welding process, the critical takeaway is that TIG welding is the right process to produce high-quality, precision welds to complete these products. The process allows better heat control and ultimately better adhesion between surfaces. All Kinetic products go through several passes of TIG welding and feature 4340 heat-treated high-strength bolts.

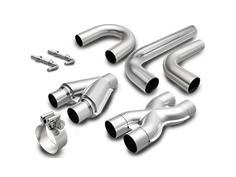

Exhaust

Although one might think that an off-road race truck wouldn’t need any form of exhaust, Jerry says, “mufflers are needed to make a race bearable for a driver.” A race like the Baja 1000 takes about 20 hours, so driver fatigue is a real concern. Camburg trophy trucks run two Magnaflow 5-inch bullet-style race mufflers to help reduce the overall volume of the exhaust. Additionally, the mufflers help to dampen annoying frequencies at specific engine speeds.

The Future of Trophy Trucks

We ended our conversation with Jerry by asking him about the future of off-road truck racing, and he gave us some interesting information about the changes we may see soon. The number one advancement is all-wheel-drive (AWD). Where trophy trucks have traditionally been rear-wheel-drive (RWD), AWD allows for a whole new level of performance. The previous constraints of AWD were ground clearance, as the need for front axles reduces overall clearance by about four inches, a big sacrifice to make while off-roading at speed. With the advent of portal axles — where the half-shaft is above the center of the wheel hub and power is transferred to each wheel via a simple gearbox — ground clearance can be maintained while adding power to the front wheels.

Don't have a Trophy Truck? SHOP ALL TRUCK EXHAUSTS

Comments