The Art of the Trophy Truck: Jerry Zaiden of Camburg Engineering

From the first moment Jerry Zaiden laid eyes on a trophy truck he was instantly hooked. The impressive machine helped fuel his passion for desert racing and ultimately led to the development of Kinetik Trucks built by Camburg Engineering – a suspension company for off-road and pre-runner vehicles.

Jerry Zaiden, president of Camburg Engineering, started his first off-road build with his friend, Jason Campbell, during his high school years. “We quickly knew the small buggy class was not for us,” Zaiden said of the 1600cc Buggy that served as a gateway into the hobby. “We built a (Ford) Ranger truck and started racing the local MDR races in Barstow and Lucern.”

Zaiden and Campbell went on to race in events like the SCORE Baja 1000 and 500 and earned multiple podiums along the way in classes such as MDR 1450, BITD 7200 and Stock Full. Their success in the Ford Ranger gave Zaiden and Campbell exposure in the racing community and the truck served as the test vehicle for various part designs they had begun creating. “So many people would have us building parts for them, so we started a business,” Zaiden said.

Launched in 1997, Camburg Engineering has grown into a leading manufacturer of “over-the-counter” high-quality off-road suspension components. The company has always drawn inspiration from desert racing and maintains all the products are “race proven.”

“We actually started with a full truck build, but part sales became very busy for us,” said Zaiden. In 2007, he and Campbell entered the first-ever 7200 mini trophy truck class in the Best in the Desert series where they finished in second place. Additionally, Zaiden and Campbell raced the latest Toyota Tundra in the Stock Full class at the 40th SCORE Baja 1000 in 2007 and used the truck the following year for Best in the Desert’s race series in Stock Full and Class 8.

“Building unlimited trophy trucks came from our desire to build the most radical off-road vehicles on the planet,” Zaiden said. “I guess it was not really a progression as much as it was the right time.”

The design for their trophy truck build was completely drawn in Solid Edge CAD software and took nearly a year to complete, much like many of the other builds produced by Kinetik Race Trucks. Once finished, the first truck was entered in its first race - the 2009 Baja 1000. “Just finishing the race was our goal,” Zaiden said. “Jason and I split driving duties and finished in about 20th place out of 50 drivers in the class.”

“We worked hard, met our goals and built a new race truck brand,” Zaiden said of Kinetik Race Trucks. Currently, there are eight designs and over 13 Camburg-built Kinetik trucks out racing. According to Zaiden the oldest truck of them still earns podium finishes.

“We will build trucks for anyone,” Zaiden said. “We like to treat everyone the same and really enjoy watching people enjoy their trucks.”

Essentially there isn’t a blueprint or guidelines other than a few safety rules to follow when it comes to the design of these trucks. Each one is a prototype in the sense that it is unique and hand built. This allows for creativity, but the initial design is the most challenging aspect for Zaiden. Each design is created in the latest CAD design software, and they do all the CNC machining, MIG and TIG welding, CNC laser cutting, tube notching and bending to create the trucks in-house.

Assembly can be done in as little as a day, or can span six months depending on the customer’s needs. Camburg offers a bare chassis allowing customers to do work themselves or Camburg can provide customers with a full, turn-key, race-ready truck.

Power options vary depending on how the truck will be used. Zaiden notes in BITD, they have a class he and Jim Riley created – 6100 – which is a “spec unlimited truck that runs an LS3 engine,” but when it comes to an “Unlimited truck, we chose Dougan Racing Engines. His 860 horsepower engines have the best results and best servicability.”

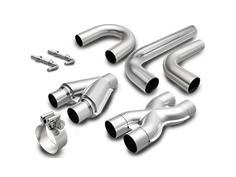

For most turn-key, race-ready trucks, Zaiden relies on parts he knows will hold up at high speeds in the desert. Among those trusted “go-to” parts are Fox Shocks, Magnaflow exhaust, FK rod ends, MOTEC electronics, Rigid Lights, Lucas Oil and of course Camburg suspension.

“We focus on quality,” Zaiden said, adding over the last few years he and Campbell have worked with some high-profile companies and racers. “When you install an exhaust, you want it to just bolt on and last. Magnaflow has perfect fitments for our trucks.”

To be successful in desert racing, Zaiden says the quality of parts is a key factor and that building a truck is time-consuming, takes a lot of preparation, but “races are won in the shop.”

Current projects Zaiden and Campbell are involved with include a Ford F-150 with Roland Sands and they are working with SCOSCHE on a Tacoma build for the 2017 SEMA Show. Visit the Camburg Engineering website for more information on Kinetik Trucks.

Comments