COLD START COLLABS: Driving Cody’s E92 BMW M3

We Invited Cody “Driving Cody” Groom to Collaborate

A few months back we invited YouTuber Cody “Driving Cody” Groom to our headquarters in Oceanside, CA, to collaborate with us on a custom exhaust solution for his 2011 BMW E92 M3. Cody was looking for an exhaust system that would be louder than his existing M Performance Exhaust while retaining the character of the E92’s renowned, naturally-aspirated 4.0L S65 V8.

INITIAL STEPS

Where to Begin?

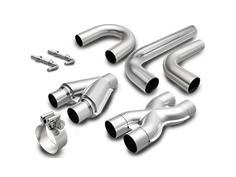

When Cody arrived, we first showed him around the office before taking him to MagnaFlow’s Research and Development Center. Cody was particularly impressed with some of the technology and customization parts we had on hand, such as our 3D scanning setup and wall of various exhaust tip options. There we explained our plan to use one our BMW M3 Exhaust Systems for the E92 M3 as a starting point, beginning with replacing his old system from the axle on back.

The reason we began with the axle-back portion of the system was that we wanted to make sure that the system fit properly under the car. Cody’s numerous aftermarket modifications to the undercarriage could impact fitment. For example, alterations to the brackets were deemed necessary in order to accommodate his E92’s rear diffuser.

No Drone Technology

Other modifications to our existing system included the addition of Helmholtz-style quarter-wave resonators. At MagnaFlow we refer to these additional chambers as NDT (No Drone Technology) resonators, because they utilize reflections of the droning frequencies normally produced by an exhaust system in order to create a passive noise-cancellation effect. As a result, these structures help eliminate the unwanted sounds which can be produced by a performance exhaust system when driving at cruising speeds.

Test Drive #1: First Impressions

After a couple weeks of testing the revised exhaust system, there were still clearly some updates that needed to be made. Cody liked the increased volume and deeper tone of the exhaust, as well as the fact that he could now hear the engine at idle. However, he also felt that some of the treble and higher-pitched, aggressive character of the S65 V8 had been muffled in the process. Additionally, he was still noticing some droning at freeway speeds and reported that downshifts didn’t seem as “crisp” as they were before.

Regarding the appearance of the exhaust system, Cody liked both the original quad-split rear 2.5” diameter tips of his old setup as well as the quad-split 3” tips on the MagnaFlow system but couldn’t quite decide between the two. However, having seen the wall of exhaust tips at our R&D Center, he understood that changing the tips to his liking wouldn’t be an issue.

EXHAUST REWORK: DAY ONE

Room for Improvement

After hearing Cody’s thoughts at that point in the development stage, it was clear to us what needed to be done to create the system he was looking for. Our target became eliminating much of the lower frequency noise, both to get rid of the remaining droning and to allow for higher frequency tones to more easily shine through, thus creating a higher pitched overall exhaust note.

The Fix

To eliminate the droning and other unwanted lower frequencies, we went with smaller NDT resonators in order to attain the desired effect. This modification allows higher pitched notes from the V8 to cut through MagnaFlow’s classic deep tone when opening the throttle. It was now time for Cody to take his ride out for another test drive.

Test Drive #2: Cody’s Critique

Not long after setting off from the MagnaFlow offices, it became obvious to Cody that the droning issue was now completely resolved. Downshifts were also much more audible after installing the new resonators, which is something that Cody felt was missing before. However, he still thought that the downshifts sounded a bit more muffled than he would like. The next step? It was time to develop new mufflers for his custom MagnaFlow exhaust system.

DEVELOPING A CUSTOM MUFFLER SOLUTION

Deleting the Mufflers to Establish A Baseline

First, we needed to get an idea of what his E92 M3 sounded like without mufflers. This meant temporarily replacing the existing mufflers with straight pipes from the resonators on back. After getting a feel for the unrestricted sound of the 4.0L V8, we could then develop a proper muffler solution from scratch.

In the meantime, Cody was trying to decide on which tips he wanted for his quad-split exit. He was leaning toward a couple carbon fiber options to go with the carbon fiber rear diffuser on his M3. Unfortunately, spacing looked like it might be an issue with the carbon fiber tips. There wasn’t enough room beneath the diffuser to keep the tips totally separate, but also no way to really weld each pair of tips together in order to eliminate potential rattling (which we would normally do for stainless steel tips). However, a final decision on the tip design could wait until the mufflers themselves had been fully developed. It was time for another test drive.

Test Drive #3: No Mufflers–The E92 Unleashed!

The result of the muffler deletes? A loud exhaust! The previously muffled downshifts? They were noticeably replaced by an aggressive, concussive bark at each flick of the paddles. It obviously wasn’t the result he was looking for in a finished exhaust, but on a short test drive it sure was a lot of fun!

EXHAUST REWORK: DAY TWO

Custom Mufflers Installed

After hearing what his M3 had to offer with unrestricted straight pipes, we decided to go with 11” mufflers instead of the 14” ones we had previously used. Our team also chose to forgo the usual stainless-steel wool packing that we utilize in most of our straight-through mufflers. The goal with these changes was to create a higher pitched exhaust tone that would allow the rowdy magic of the BMW’s engine to shine through.

The result? After a quick test spin Cody knew that he finally had the sound he was looking for. It was time to create a final version of his custom exhaust built to MagnaFlow production standards.

THE RESULT

A Finished Product

Using the prototype design that we had been working on with Cody since the beginning, we went ahead and created a production-quality version with all the stainless steel, CNC precision robotic construction and mandrel bent piping that our customers have come to expect from MagnaFlow’s premium performance exhaust products. In the end, Cody decided to go with 3.5” polished stainless-steel tips, because he felt in the end that they matched the look of his car much more than the carbon fiber tips.

Final Test Drive

At last, it was time for Cody to take his finished MagnaFlow custom exhaust on a final test drive. He loves the new sound of his exhaust, with the shouty character of the M3’s engine allowed to cut through MagnaFlow’s deep signature exhaust tone whenever he decides to open the throttle. Downshifts now crackle with a dramatic flair that had been lacking from some of our earlier attempts. To top things off, he can now actually hear the BMW idle clearly as well, unlike with his previous system.

Another Satisfied MagnaFlow Fan

We at MagnaFlow are so happy that we were able to help Cody create a dream exhaust system for his E92! We wish him and his newly sonorous Beemer many exuberant downshifts and drone-free drives for years to come. It’s always great to see fans enjoying our handiwork and we look forward to seeing what Cody does next.

Have questions about our products? Give us a call at 1-800-990-0905, and we’d be happy to help.

SHOP EUROPEAN PERFORMANCE

Watch Driving Cody's Recap

Comments